Industries we have served

Infrared Thermography Testing

Home » NDT Services » Infrared Thermography Testing

Thermal Imaging, Thermography testing ,INFRARED THERMOGRAPHY TESTING – INFRARED THERMOGRAPHY FOR PLANT INSPECTION – ELECTRICAL AND MECHANICAL, HELPS IN IDENTIFYING LOOSE, OXIDIZED, MALFUNCTIONING ELECTRICAL PARTS EMITTING HOT SPOTS AND SAVES MONEY YEARLY ON EXCESSIVE ELECTRICITY CONSUMPTION.

Infrared thermography Services is a technique of using a non-contact & non-destructive Infrared Scanning Camera to detect invisible Infrared thermal radiation of objects, and recording these pictures as thermal images called “Thermograms” to assist in identifying potential equipment failures.

Infrared thermography Services is a proactive troubleshooting and predictive maintenance tool. The test method uses an infrared imaging to detect, display and record thermal patterns and temperature across the surface of an object

Infrared thermography is a valuable tool for condition monitoring and preventive maintenance. Not only does it allow you to detect thermal abnormalities of machines, but it lets you do so in a non-intrusive, hands-off way while still getting results in real-time.

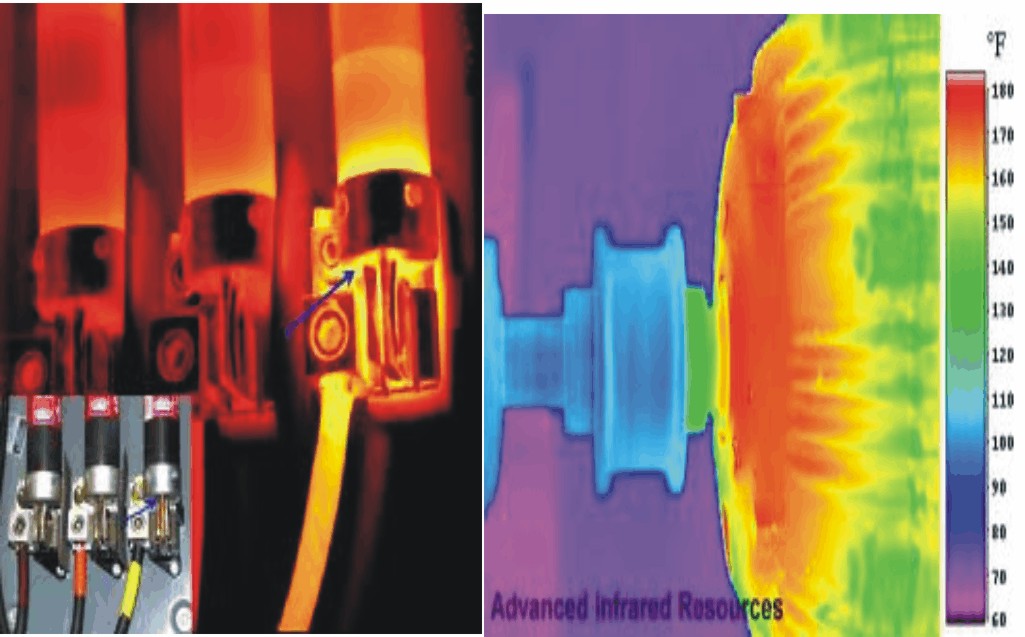

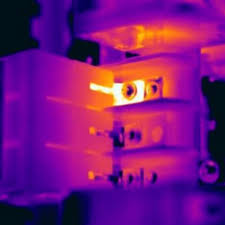

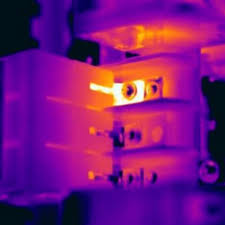

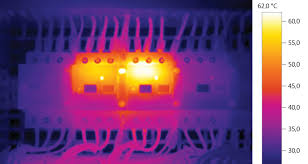

A LOOSE / OXIDISED WIRE DRAWS HIGH CURRENT WHICH IS NOT VISIBLE BY HUMAN EYE, INFRARED THERMOGRAPHY CAMERA DETECTS THE HEAT EMITTED FROM IT AND HELPS IN IDENTIFYING THESE HOT SPOTS.

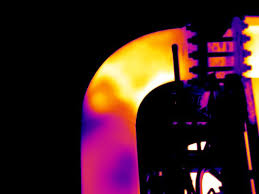

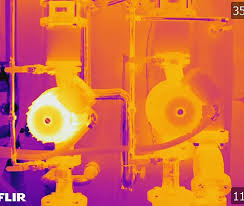

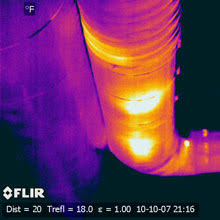

ALSO VERY EFFECTIVE IN IDENTIFYING HOT SPOTS IN MECHANICAL DEVICES – PUMPS & MOTORS, PIPING INSULATION FOR STEAM LINES, COLD NITROGEN LINES AS SHOWN IN THE FOLLOWING PICTURES –

THERMOGRAPHY TESTING OF THE PLANT PIPING SHOWING HOT SPOTS ON THE SURFACE

INDICATING INSIDE CORROSION / LEAKAGE.

THERMAL IMAGING SHOWING THE FIRST MOTOR EMITTING MORE HEAT , THE REASON FOR THIS CAN BE DEFECTIVE BEARING, ECCENTRICITY, EXCESSIVE FRICTION. THIS WILL EVENTUALLY LEAD TO FAILURE.

THERMOGRAPHY TESTING OF THE INSULATED PLANT PIPING INDICATING LEAKAGE IN THE INSULATION SURFACE RESULTING IN LEAKAGE OF THE STEAM FROM THE PIPES AND HEATING THE PIPE SURFACE.

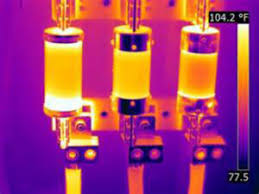

ELECTRICAL CONNECTOR SHOWING HOT SPOTS WHICH INDICATES LOOSE CONTACT, OXIDIZED SURFACE OR CRIMPING PROBLEMS, THESE TYPES OF SPOTS USE MORE ELECTRIC CONSUMPTION AND ENERGY LOST IN THE FORM OF HEAT GENERATED.

These types of problems generate hot spots on the surface and it can be easily identified in the Infrared Thermography Inspection.

Applications – Electrical Panels, Motors, Insulated Vessels and Pipes , Rotary Kilns, Steam Turbine and Hydroelectric Generators, MCC & PCC Panel, Switchyard

ELECTRICAL COMPONENTS SHOWING ANOMALY AND NEEDS RECTIFICATION.

HOT WIRE SEEN IN THE PICTURE AND THE CAUSE TO BE IDENTIFIED.