Industries we have served

Liquid Penetrant Testing

Home » NDT Services » Liquid Penetrant Testing

Liquid penetrant is an NDT method that utilizes the principle of capillary action in which liquid of suitable physical properties can penetrate deep into extremely fine cracks or pitting that are opened to the surface without being affected by the gravitational force.

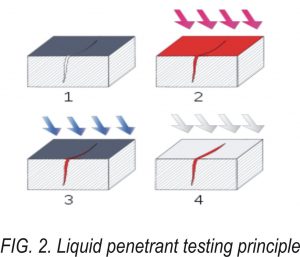

Liquid penetrant testing (PT) method consists in depositing on the object surface of a special liquid, which will be drawn into any surface defect by capillary action. A liquid with high surface wetting characteristics is applied to the surface of the part and allowed time to seep into surface breaking defects (Fig. 2). Following removal of excess penetrant an application of a developer reverses the capillary action and reveals the presence of the flaw so that it can be visually inspected and evaluated.

The PT method can be used on metallic parts of civil engineering equipments. Liquid penetrant inspection generally involved the following sequence:

Pre-cleaning

At this stage, surface of the inspected item is cleaned to avoid the presence of any dirt that may close the opening of discontinuity. Cleaning is accomplished by various methods such as vapor cleaning, degreasing, ultrasonic cleaning etc.

Penetrant application

Once the surface is cleaned, penetrant either in the form of dye penetrant or fluorescence penetrant is then applied. The application of penetrant can be achieved either by dipping, spraying or brushing depending on the nature or item to be inspected. This penetrant is then allowed to remain on the surface for some duration. Such duration is termed as a dwell time. During this period, if there is any discontinuity, penetrant will penetrate deep into it.

Removal of excess penetrant

Excessive penetrant need to be removed from the surface to allow inspection to be made. Such removal can be achieved by applying water, proper solvent or emulsifier followed by water (depending on the type of penetrant used) on the surface. At this stage, all unwanted penetrant will be removed from the surface, leaving only those trapped inside the discontinuity.

Developer application

Developer is then applied to the surface of the inspected item. This developer either in the form of dry powder or wet developer acts as a blotting paper which draws penetrant out of the discontinuity.In doing so, penetrant will bleed to form an indication whose shape depends upon the type of the discontinuity presence in the material. Such an indication is recorded either by the application of a special tape or by taking its photograph

Post-cleaning

Application of penetrant and developer causes the surface to be contaminated. Thus, upon completion of the inspection, it is important for the item to be cleaned so that no corrosive material remains on its surface that may affect its serviceability.

As for other NDT methods, liquid penetrant has its own advantages and limitations.

Advantages

- Simple to perform

- Inexpensive

- Applicable to materials with complex geometry.

Limitations

- Limited to detection of surface breaking discontinuity

- Not applicable to porous material

- Require access for pre- and post-cleaning

- Irregular surface may cause the presence of non-relevant indication