Industries we have served

Ultrasonic Thickness measurement

Home » NDT Services » Ultrasonic Thickness measurement

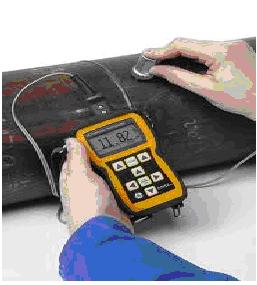

One of the most widespread NDT methods in mechanical equipment of industrial installations for the characterization of erosion and deterioration is the thickness measurements with the Ultrasonic method. We offer high level thickness measurement services on pipes, pressure vessels, boilers, tanks etc, by experienced and certified inspectors.It is also called as Ultrasonic wall thickness measurment, Thickness measurement.

Thickness measurement is achieved by placing the UT probe on the object surface. Local or general reductions of thickness can be located and measured with high precision. The instruments that are used for the measurement are portable and light with possibilities of saving the measurements data in a data logger.

The use of different probes offers the capability to perform thickness measurements in inaccessible surfaces, on very thin plates, on high temperature environments, above paint (thru-coat or echo to echo functions) as well as on surfaces with intense local corrosion without any surface smoothing required (use of pencil type probes).

Advantages of the method:

- Quick measurements with direct results.

- High precision measurements.

- The inspected object can be in-service.

- No particular surface preparation required, minor wire brushing is needed.

- Measurements can be made without removal of the paint.

- Measurements can be made in inaccessible regions using suitable probes.

- Corrosion rate calculations can be made with thickness reduction observations with repeated measurements in the same points.

- Measurements on high temperature surfaces possible.

- Display of corrosion profile on B-Scan form.

ULTRASONIC LOW THICKNESS MEASURMENT

The equipment normally used for Thickness measurement has a

Starting range which starts from 1 or 1.2 mm and goes upto 225 mm/ 300 mm.

For Thin sheets thickness measurement with precision specialized Thickness Measurement equipment are needed with very high frequency probes with delay tips so that thin thickness can be resolved.

We have very efficient low thickness measurement for this purpose which can start from 0.13 mm. thickness onwards. Low thickness checks are required for Expansion bellows sheet measurement and other low thickness job requiring thin plates.