Industries we have served

Magnetic Particle Testing

Home » NDT Services » Magnetic Particle Testing

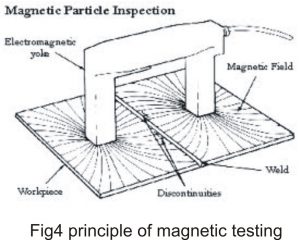

Magnetic particle testing (MT) is a NDT method that utilizes the principle of magnetism.Material to be inspected is first magnetized through one of many ways of magnetization. Once magnetized, a magnetic field is established within and in the vicinity of the material. Finely milled iron particles coated with a dye pigment are then applied to the specimen. These magnetic particles are attracted to magnetic flux leakage fields and will cluster to form an indication directly over the discontinuity.

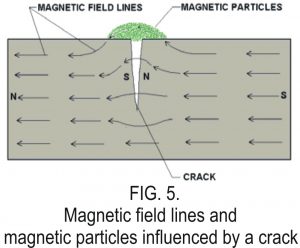

They provide a visual indication of the flaw. The presence of surface breaking and subsurface discontinuity on the material causes the magnetic field to ‘leak’ and travel through the air. Such a field is called ‘leakage field’. When magnetic powder is sprayed on such a surface the leakage field will attract the powder, forming a pattern that resembles the shape of the discontinuity. This indication can be visually detected under proper lighting conditions.

Figures 4 and 5 present the principle of magnetic Magnetic particle (MT) testing is used to locate surface and slight subsurface discontinuities or defects. MT is only applicable to magnetic materials. It can be used on metallic parts of civil engineering equipments.

There are many methods of magnetizing materials. The use of permanent magnet is one of the ways of magnetization. However, in many cases the use of electromagnet is considered as a more superior and effective way of magnetization. Another way of creating magnetic field in a material is by the use of coil carrying current.

In this way, a longitudinal magnetic field would be able to be established in long items such as bars and cylinders. Circular magnetic field on the other hand is produced by allowing current flowing along the cylindrical material. Induction of magnetic field into the material to be inspected can be achieved by the use of either alternating current (AC) or direct current (DC). In general the use of DC would produce magnetic field deeper below that surface that allow subsurface discontinuity to be detected.

Discontinuities can be best detected when the direction of magnetic field is perpendicular. The chance of detection reduces as the angle between the magnetic field and the plane of defect decreases. When the angle between the magnetic field and the plane of defect is zero, i.e. the magnetic field is parallel with the plane of defect then the chance of detection becomes zero.

The application of MT involved the following sequence:

- Pre-cleaning

- Magnetization

- Application of magnetic powder

- Demagnetization

The advantages and limitations of using MT method are as follows:

Advantages

- Inexpensive

- Equipment are portable

- IEquipment easy to operate

- Provide instantaneous results

- Sensitive to surface and subsurface discontinuities

Limitations

- Applicable only to ferromagnetic materials

- Insensitive to internal defects

- Require magnetization and demagnetization of materials to be inspected

- Require power supply for magnetization

- Coating may mask indication

- Material may be burned during magnetization