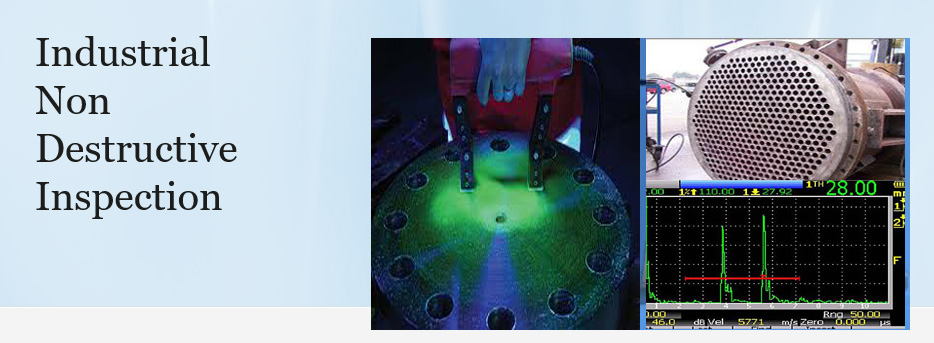

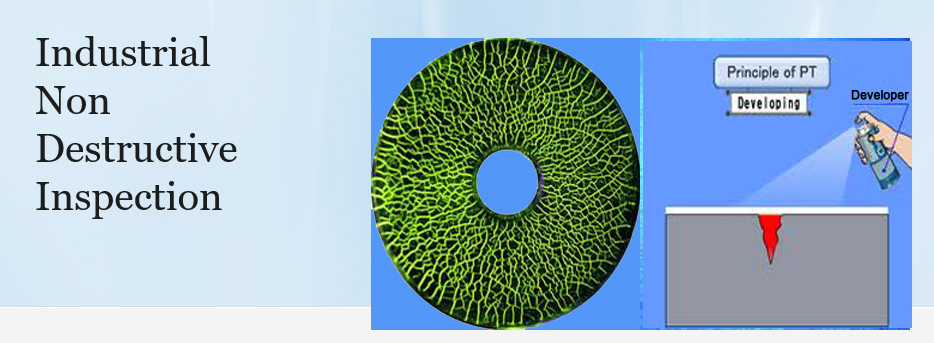

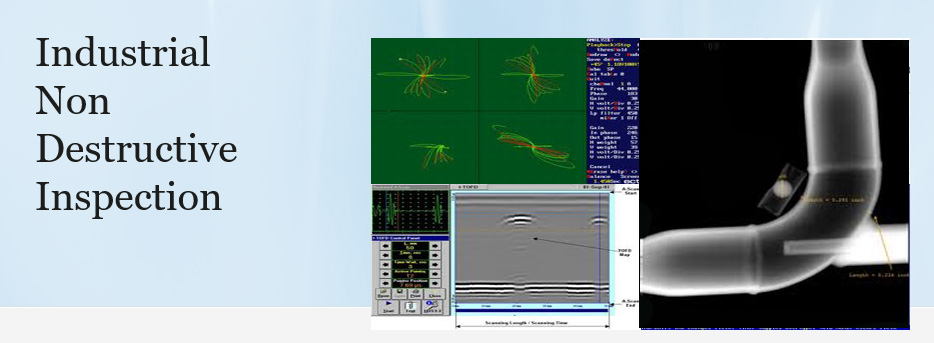

Non-destructive testing (NDT) is a noninvasive technique for determining the integrity of a material, component or structure. Because it allows inspection without interfering with a product's final use, NDT provides an excellent balance between quality control and cost-effectiveness. The main goal of NDT is to predict or assess the performance and service life of a component or a system at various stages of manufacturing and service cycles. NDT is used for quality control of the facilities and products, and for fitness or purpose assessment (so-called plant life assessment) to evaluate remaining operation life of plant components (processing lines, pipes and vessels). NDT inspection of industrial equipment and engineering structures is important in power generation plants, petroleum and chemical processing industries, and transportation sector. State-of the- art methodology is applied to assess the current condition, fitness-for-service, and remaining life of equipment. NDT inspection provides basic data helping to develop strategic plans for extending plant life. Applications in various industries - Power Generation, Automotive,Petrochemical and chemical, Manufacturing,Oil and Gas industry, Paper Industry, Shipping industry - Barge, ships and rigs , Metals and mining industry. The need for quality based Non Destructive Inspection in various industries by technically competent and experienced persons had led to the foundation of this company. The experience gained from allied industries for 2 decades from different continents in onshore and offshore based projects has helped us immensely in providing the technical inputs required by various industries. The experience we had gained in the following industries has helped us immensely in shaping up the company and expanding our activities from Industrial NDT Training , NDT services , NDT consultancy , NDT expedition at projects and sites, Motivational and orientation programmes to the NDT personnels in organizations.

- Welcome to Industrialndt.com

We provide NDT Services / PMI testing / Radiography services at Anand, Ankleshwar,Jhagadia, Panoli ,Dahej, Bharuch, Surat Hazira , Vapi , Anjar and Kutch.